Ebe P bụ ibu a etinyere, n; D bụ dayameta nke bọl ígwè, m; d bụ dayameta nke intentation, m; H bụ omimi nke intentation, m.

Ule ule: HG2-168-65 Brinell Usoro Nlere Anya Maka Plastics

2) Shero Ikpe

N'okpuru ime ihe ngosi nke nwere otu akọwapụtara, omimi nke agịga na-aga n'ime ụdị mgbe a na-ewere oge oge niile dị ka ihe atụ dabara adaba. E kewara isi ike na-ekewa n'ime mmiri na mmiri d. nke mbụ ga-emetụta ihe ndị na-adịghị mma; Nke ikpeazụ bara uru na ihe ndị siri ike.

Ule ule: GB / T 2411-2008 usoro nnwale usoro maka plastik

3) Rockwell siri ike

Ihe isi ike Rockwell nwere usoro ngosipụta abụọ. Ozo nke Sckale Bort Scornell na-enwe obere bọl siri ike, na ibu site na ibu mbu, wee laghachi na mbido mbụ Uru, gosipụtara na akara HR. Ofzọ a ga - esi tinye ihe ndị siri ike, kewara n'ime r, m, l.

Ule ule: GB / T 9342-88 RockWell usoro nnwale maka plastik

② rockwell H ihe siri ike na otu bọọlụ nke bọl nke ọma, n'okpuru ihe akọwapụtara nke ọma, pịa n'ime omimi nke ụdị ahụ maka uru siri ike, kwupụtara na H.

Ule ule: GB / T 3398-2008 usoro nnwale siri ike maka rọrọ plastic

4) Barcol siri ike

A na-abanyekwa otu ihe dị ka ọkọlọtọ n'okpuru nrụgide nke oge opupu ihe ubi.

Ntuli mmiri nke nwere ihe ngosi a kapịrị ọnụ na mmiri ọkọlọtọ na ụdị mmiri, omimi nke inwe obi ike nke ihe ndị a. Usoro a dabara adaba maka ikpebi ihe mgbochi nke eriri na ngwaahịa ha, yana ike itinye aka na ike nke plastic ndị ọzọ siri ike.

Ule ule: GB / T 3854-2017 Plastic Plastics Bachmann (Bakel)

Usoro nnwale siri ike.

6. creep

N'okpuru ọnọdụ okpomọkụ na iru mmiri, nrụpụta nke ihe ahụ ga-abawanye n'oge a na-aga n'ihu na-aga n'ihu.

N'okpuru ọnọdụ okpomọkụ na ọnọdụ iru mmiri mgbe niile, ihe a na-aga n'ihu na-aga n'ihu na-aga n'ihu na-aga n'ihu, nrụrụ na-abawanye na oge; Mmebi nke ji nwayọọ nwayọọ gbakere mgbe mwepụ nke mpụga, a na-akpọ ihe a dị egwu creep (creep).

A na-akpọ ihe a dị egwu. N'ihi ọdịdị dị iche iche nke mpụga, a ga-ekewakarị ya na tensile crep, crepday creep, shaar creep ma na-agbada.

Accountlọ Ọrụ Ule: GB / T 11546-2022 Mkpebi nke Plastics

7. ike ọgwụgwụ

Ike ọgwụgwụ (ike ọgwụgwụ) bụ ihe a na-egosi maka nrụgide nke cyclic ma ọ bụ ụdị mgbanwe nke usoro nke mpaghara na ntụpọ n'ime ime na usoro mmepe. Ike ọgwụgwụ bụ usoro nke mgbanwe usoro nhazi nke usoro nke ime ememe mere mgbe a na-edobe ihe na-akpata ọgba aghara na-agbanwe ókè.

8. Ọchịchọ na iyi

Ihe ndị ọzọ na ibe ha, enwere mkpofu dị iche iche n'etiti ibe ha ma ọ bụ ihe dị iche iche na-enweghị isi, ike dị n'etiti ibe ha na-ezo aka na-enweghị mgbagha. Comeffief nke esemokwu ma yie ihe eji mara ihe eji eme ihe.

1) Achịcha efu (Coloffiefs nke esemokwu)

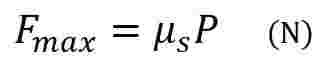

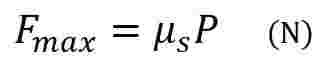

Oke Startic Fress FMAX dị ka usoro a

na

ebe μk bu onu ogugu nke igba ugha, ma p bu nrụgide dị mma, N.

2) Abration

Onu ogugu nke ihe mberede mgbe esemokwu maka oge ma obu oge nke oge a na-akpọ.

Onu ogugu nke ihe a ghaghi iju ajuju a oge ụfọdụ ma ọ bụ usoro a na-akpọ nza. Kacha mma iguzogide ihe a na-eme, belata oke nke nza.

Ule Ahịa: GB / T 3960-2016 na-acha uhie uhie na-eyi usoro nnwale maka plastik GB / T 5478-2008 mpịakọta usoro.

na

na

na

na

na

na